Conventional vehicles use gasoline or diesel to power an internal combustion engine. Hybrids also use an internal combustion engine—and can be fueled like normal cars—but also have an electric motor and battery.

By using both a conventional engine and electric motor, the best hybrids achieve significantly better fuel efficiency than their non-hybrid counterparts. They also pollute less and save drivers money through fuel savings.

The most advanced hybrids have larger batteries and can recharge their batteries from an outlet, allowing them to drive extended distances on electricity before switching to gasoline or diesel. Known as "plug-in hybrids," these cars can offer much-improved environmental performance and increased fuel savings by substituting grid electricity for gasoline.

Hybrid car features

The addition of a battery-powered electric motor increases the fuel efficiency of hybrids in a number of ways.

Like the switch that turns off your refrigerator's light bulb when the door is closed, "idle-off" is a feature that turns off your car's conventional engine when the vehicle is stopped, saving fuel. The battery provides energy for the air conditioner and accessories while the vehicle idles at stoplights or in traffic, and the electric motor can start the vehicle moving again. If needed, the conventional engine will reengage to provide more power for acceleration.

"Regenerative braking" is another fuel-saving feature. Conventional cars rely entirely on friction brakes to slow down, dissipating the vehicle's kinetic energy as heat. Regenerative braking allows some of that energy to be captured, turned into electricity, and stored in the batteries. This stored electricity can later be used to run the motor and accelerate the vehicle.

Having an electric motor also allows for more efficient engine design. This "power assist" feature helps reduce demands on a hybrid’s gasoline engine, which in turn can be downsized and more efficiently operated. The gasoline engine produces less power, but when combined with electric motors, the system’s total power can equal or exceed that of a conventional vehicle.

The most efficient hybrids utilize "electric-only drive," allowing the vehicle to drive entirely on electricity and use less fuel. In hybrids that can't be plugged-in, electric-only drive is typically only utilized at low speeds and startup, enabling the gas or diesel-powered engine to operate at higher speeds, where it’s most efficient.. Most plug-in hybrids—which tend to have larger batteries and motors—can drive entirely on electricity at relatively high speeds for extended distances (typically 10 to 30 miles).

Different hybrids also use different types of "drivetrains," the mechanical components that deliver power to the driving wheels. Learn about the implications of different hybrid drivetrains here.

Differences between hybrids and other EVs

Hybrids that can't be recharged from an outlet aren't generally considered to be electric vehicles, as they rely exclusively on gasoline or diesel for energy. Plug-in hybrids, described above, are considered electric vehicles, along with battery electric and hydrogen fuel cell vehicles. Learn more about how plug-in vehicles work.

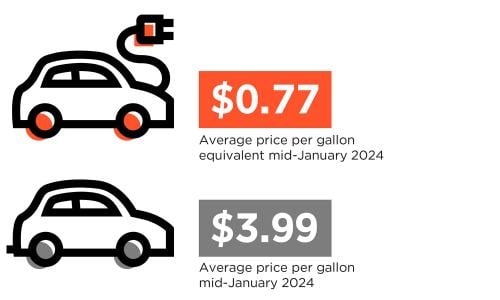

Battery electric vehicles only use an electric motor and battery, eschewing conventional engines altogether. Because they don't use gas or diesel, battery electrics are often cleaner and cheaper to fuel than hybrids and conventional vehicles. Learn more about how battery electrics work.

Hydrogen fuel cell vehicles power an electric motor and battery by converting stored hydrogen gas to electricity using a fuel cell. These vehicles are only beginning to come to market, but offer great potential as a low-carbon alternative to conventional cars and trucks as they have no tailpipe emissions, reduced global warming emissions, and can be refueled at a filling station similar to a gasoline vehicle. Learn more about how fuel cells and fuel cell vehicles work.

Learn more about electric vehicle technology here, including its potential as a nationwide oil-saving solution.